304 stainless steel corrugation, how much temperature can it

It is well known that stainless steel corrugated compensator is not only a single device component, in fact, the metal hose can also be called this, mainly because for such compensator, sometimes a device component has several names, but when it comes to the specific model is not the same.

1. Metal hose is made of 1Cr18Ni9Ti stainless steel and has strong corrosion resistance.

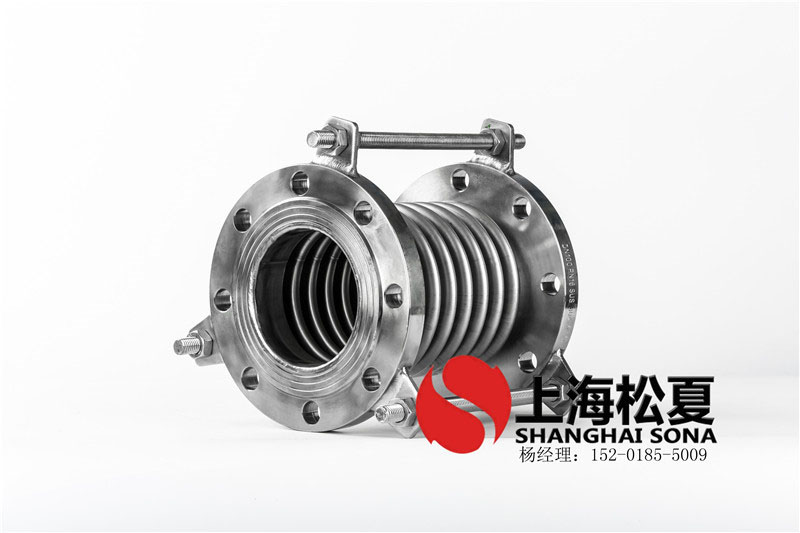

2. The stainless steel corrugated compensator hose is a thin-walled stainless steel tube formed by hydroforming. It has strong flexibility, flexibility, bending and anti-vibration ability, and the braided net sleeve is strengthened and protected to make it have higher bearing capacity.

3. The connection of the two ends of the hose of the stainless steel corrugated compensator can be made into other connection modes besides the standard of the thread and flange, which is convenient for connection and use.

4. The product is not only suitable for matching with rotary joint, but also widely used for flexible connection of multi-fluid medium transportation.

Stainless steel corrugated compensator installation matters needing attention:

1, strictly prohibit mechanical damage flange sealing surface;

2, can not use chlorine cleaning agent live wire brush to remove dirt in metal hose.

3. When choosing the metal hose, in order to install it conveniently, please choose the metal hose with loose sleeve flange as far as possible.

4. The medium must not be corrosive to the bellows material. The chloride content in the medium should be less than 25PPM.

5, strictly install the correct installation of the icon installation;

6. The surface of metal hose should be protected to prevent welding slag and arc ignition from burning metal hose during welding operation.

7, should not bend along the root of the metal hose, there should be no dead bend.

8, strictly prohibit twisted installation of metal hose.