RUBBER EXPANSION JOINTS FAQ

Q: What is a rubber expansion joint?

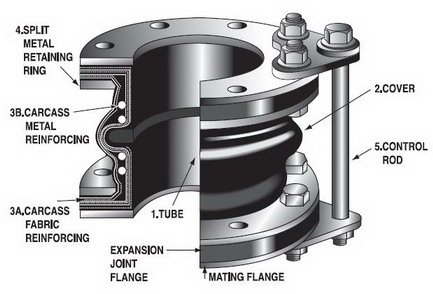

A: A rubber expansion joint is a flexible connector consisting of natural or synthetic elastomers, fabric and when necessary metallic reinforcements. The rubber expansion joint is used to provide stress relief in piping systems due to thermal and mechanical vibration and/or movement.Q: What are the main components of a rubber expansion joint?

A:

1.Tube: Protective leak proof lining made of synthetic or natural rubber dependent on service requirements.

2.Cover: The exterior surface of the joint formed from natural or synthetic rubber as service dictates

3A.Fabric reinforcement: The carcass fabric reinforcement is the flexibility and supporting member between the tube and cover.

3B.Metal reinforcement: Wire or steel rings imbedded in the carcass used to strengthen the joint.

4. Retaining rings: Must be used to distribute the bolting load and assure a tight seal. The rings are installed directly against the back of the flanges of the joint and bolted through to the mating piping flange.

5.Control rod: Used to limit the axial movements during operation, and prevent the joint from exceeding its movement capabilities. The rods attach the mating flange and expansion joint. Typically used on piping joints, but can be installed on most any joint when required

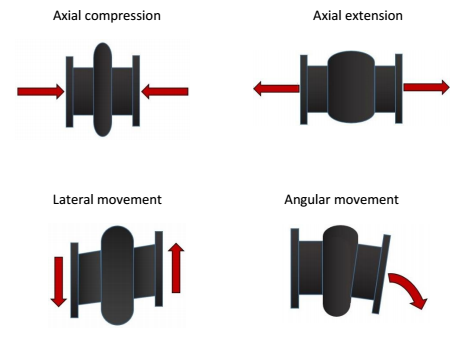

Q: What types of movements will a rubber expansion joint handle?

A: A rubber expansion joint will allow for the following movements:

1.Axial compression : The dimensional reduction or shortening of the face to face parallel length of the joint measured along the longitudinal axis.

2.Axial elongation : The dimensional increase or lengthening of face to face parallel length of the joint measured along the longitudinal axis.

3.Traverse or later movement : The movement or relating displacement of the two ends of the joint perpendicular to its longitudinal axis.

4.Vibration: The movement of the joint due to vibrations which are effectively intercepted and insulated against transmission to the remainder of the system.

5.Angular movement : The displacement of the longitudinal axis of the joint from its initial straight line position ( a combination of axial elongation and axial compression).

6.Torsional movement : The twisting of one end of the expansion joint with respect to the other end about its longitudinal axis.

7. Concurrent movements : The combination of two or more of the above listed movements. This value is expressed as the Resultant Movement.