PTFE Lined Rubber Expansion Joints

PTFE Lined Rubber Expansion joints are designed for tough demanding corrosive chemical applications. PTFE is short for Polytetrafluoroethylene, also known as Teflon, PTFE has excellent chemical stability and corrosion resistance, it’s one of the best corrosion resistance material. It offer a good life span in aggressive chemical media, where other polymers are not resistant. The PTFE liner is suitable for all commonly used liquids.

PTFE Lined Rubber Expansion Joints combine the best features of PTFE and offer superior stability to chemicals, absorbs displacement and vibration of piping equipment used in various industries ( Chemical, Petrochemical Process Facilities and Highly

Corrosive Industiral Piping , Pollution Control Systems, Pulp and Paper Industry)

MATERIALS

Rubber Joint is manufactured from independent rubber layers and reinforcements that are vulcanized together after being molded or formed.

With over 10 rubber elastomers available and our experts may assist customers select the most appropriate rubber polymer for your requirements. Including NR, NBR, EPDM, PTFE, FKM, Neoprene, butyl rubber , etc

l Widely used in all corrosive environments

l Integral flange design, no gaskets required

l high lubricating property

l Good aging resistance

l Higher pressure rating than conventional expansion joint

l High strength and simple to install.

l Nonadhesive.

FLANGES

Carbon steel as standard. Also available in zinc plated or hot dip galvanized carbon steel, Stainless steel 304,316, QT450, Q235

Flanges drilled to EN, BS,DIN, ANSI, JIS, standards or any specific dimension.

PTFE Lined Rubber Expansion Joints combine the best features of PTFE and offer superior stability to chemicals, absorbs displacement and vibration of piping equipment used in various industries ( Chemical, Petrochemical Process Facilities and Highly

Corrosive Industiral Piping , Pollution Control Systems, Pulp and Paper Industry)

MATERIALS

Rubber Joint is manufactured from independent rubber layers and reinforcements that are vulcanized together after being molded or formed.

With over 10 rubber elastomers available and our experts may assist customers select the most appropriate rubber polymer for your requirements. Including NR, NBR, EPDM, PTFE, FKM, Neoprene, butyl rubber , etc

FEATURES

l Resistance to most chemicalsl Widely used in all corrosive environments

l Integral flange design, no gaskets required

l high lubricating property

l Good aging resistance

l Higher pressure rating than conventional expansion joint

l High strength and simple to install.

l Nonadhesive.

FLANGES

Carbon steel as standard. Also available in zinc plated or hot dip galvanized carbon steel, Stainless steel 304,316, QT450, Q235

Flanges drilled to EN, BS,DIN, ANSI, JIS, standards or any specific dimension.

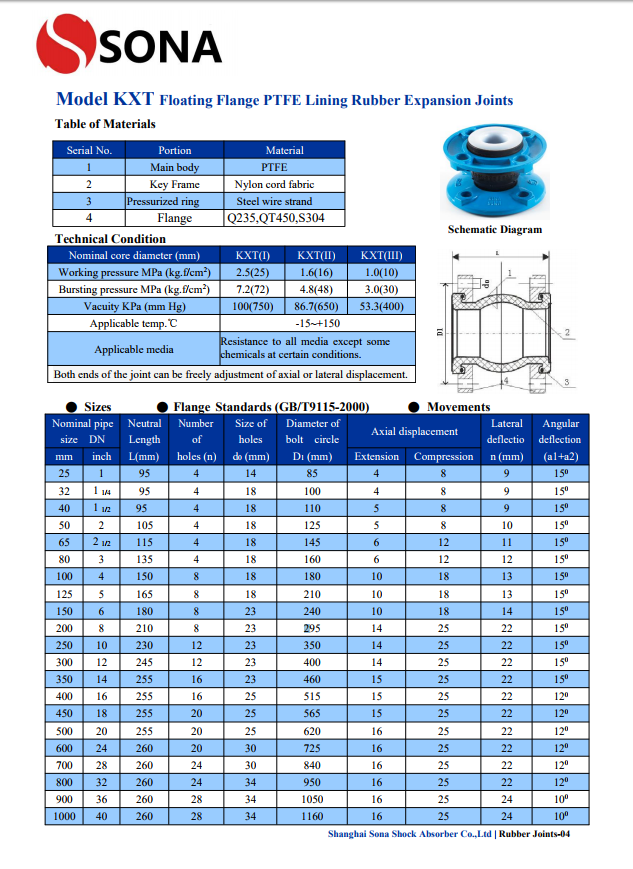

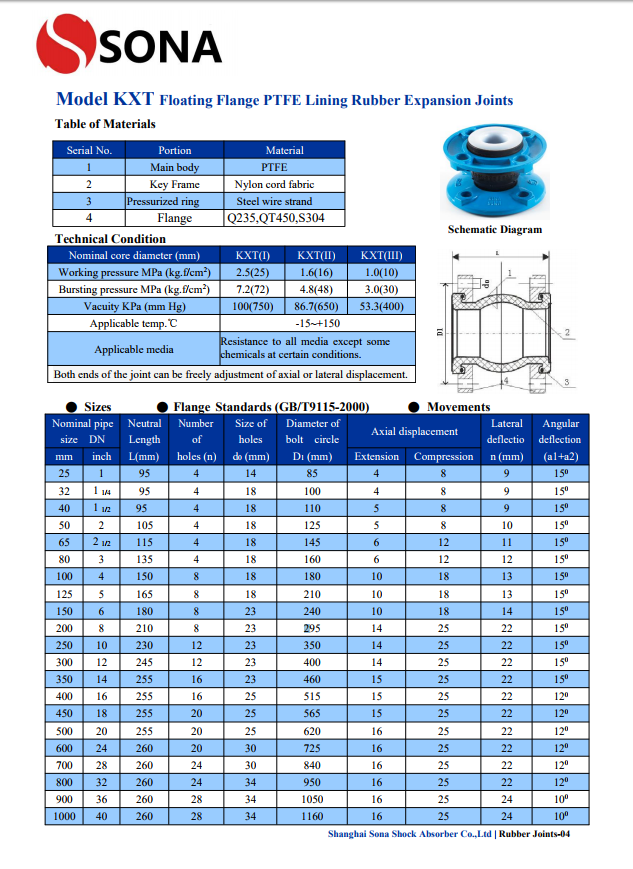

PRODUCT

PARAMETRS TABLE